DAMPER

FLOW CONTROL DAMPER

HI AIR KOREA(HAK) FLOW CONTROL DAMPERS are used to regulate the airflow rates to ensure the required condition of HVAC system. This can be done manually or automatically depending on the requirement of the system. These dampers can be also supplied with ATEX Directive 2014/34/EU for explosive atmosphere installations.

HAK FLOW CONTROL DAMPERS include AUTOMATIC MODULATING DAMPER and MANUAL BALANCING DAMPER. These dampers can be manufactured to fit both rectangular and circular ducts.

MODULATING DAMPERS can be fitted with electric or pneumatic actuators which shall include limit switches or proximity sensors that detect the position of the damper blades which in turn can be interfaced with monitoring and control system.

These dampers can operate at temperatures between -40 ~ +60℃ but subject to change depending on the selected components.

- FEATURES

- The maximum size of the single type is 1,400 mm(W) and 1,400 mm(H), and mullion type is 2,900 mm(W) and 2,900 mm(H).

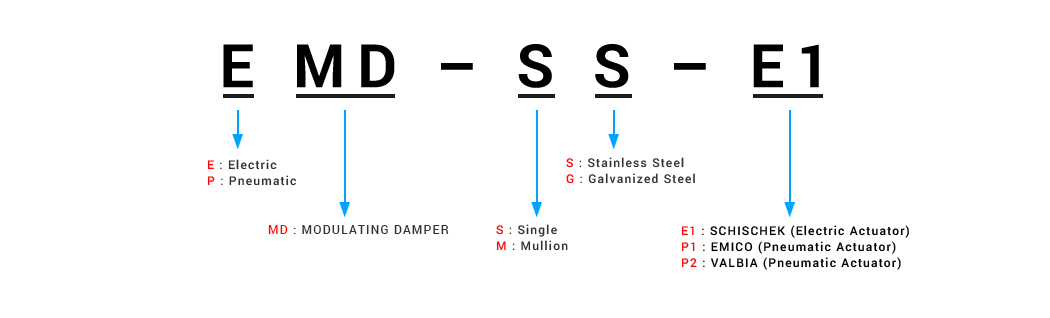

ELECTRIC MODULATING DAMPER (EMD)

-

The electric actuator requires 24 to 230 VAC/DC of electrical supply to operate the damper blades.

The electric actuator is modulated by control signal (4-20 mA, 0-10 VDC).

PNEUMATIC MODULATING DAMPER (PMD)

- The pneumatic actuator requires a supply of 5~8 bar of clean/dry instrument air to open the damper blades. The pneumatic positioner is modulated by control signal (4-20 mA, 0-10 VDC). The damper blades shall close when instrument air is cut-off or pressure is too low.

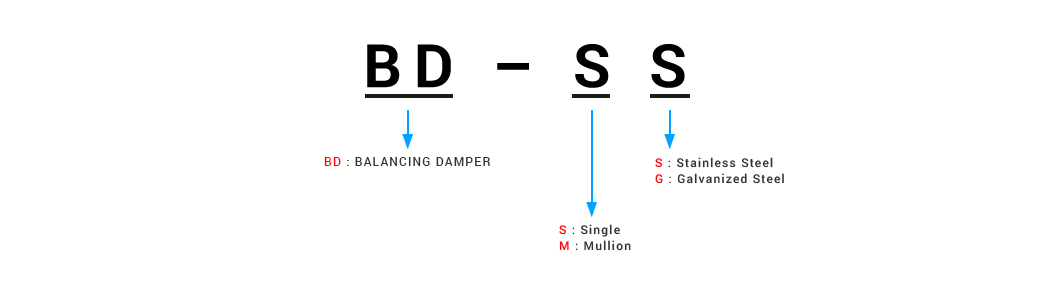

BALANCING DAMPER (BD)

- A handle is provided at the side of the damper casing for operators to control the damper blades. A quadrant plate installed with the handle gives a visual indication the blades position.

STANDARD CONSTRUCTION

Part Material Thickness Finishing Casing Carbon steel 3 ~ 10 mm Painted / Galvanized Stainless steel 3 ~ 10 mm Passivation Blades Galvanized steel 1.6 mm x 2 (Double skin) - Stainless steel 1.5 mm x 2 (Double skin) Passivation Shafts Carbon steel Φ19 Galvanized Stainless steel Φ19 Passivation Linkage Carbon steel 3 ~ 8 mm Painted / Galvanized Stainless steel 3 ~ 8 mm Passivation Linkage bar Carbon steel 3 ~ 8 mm Painted / Galvanized Stainless steel 3 ~ 8 mm Passivation Side seal Stainless steel 0.25 mm - Bearings (Bush type) Stainless steel or Brass - - - OPTIONS

- Local Control Switch

- Valve Board

- Black start air bottle

- ATEX Certificate

- Enclosure modification

- Witnessed leakage test

- CAPACITIES

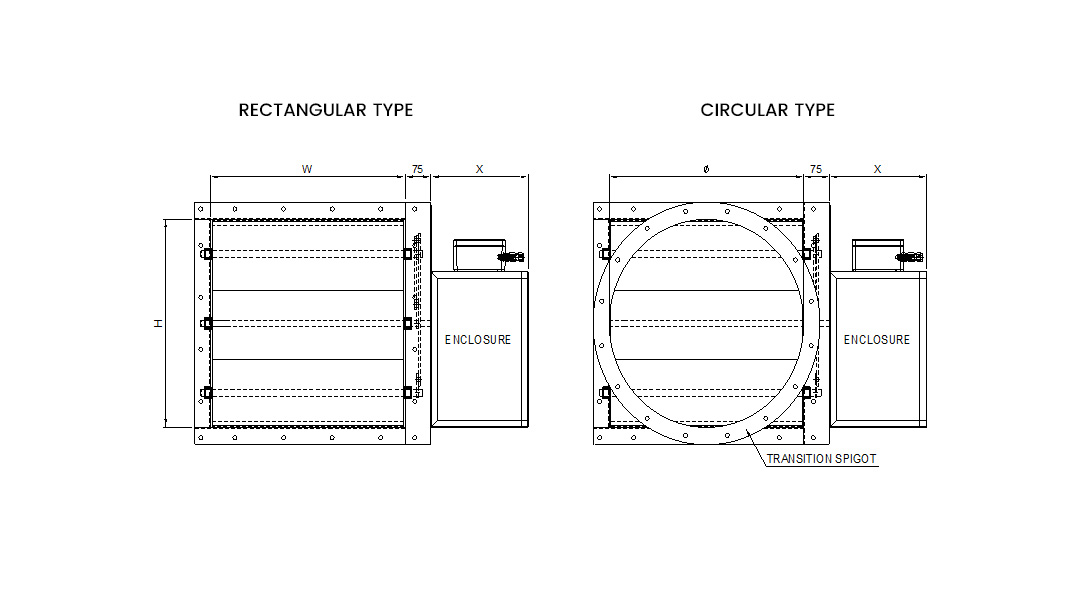

GENERAL ARRANGEMENT DRAWING

NOTES

- 1. Standard flange drilling is in accordance with ISO 15138:2007 ANNEX E

- 2. Transition spigot can be added on request

- 3. Enclosure size "X" (If required)

TYPE "X" REMARK PNEUMATIC Min. 225 ㎜ / Max. 420 ㎜ With enclosure ELECTRIC Min. 180 ㎜ / Max. 300 ㎜ With enclosure WEIGHT FOR FLOW CONTROL DAMPER

Weight (kg, Without actuator) Height

(H, mm)Width (W, mm) 100 200 300 400 500 600 700 800 900 1000 1100 1200 100 7 9 11 15 17 20 22 24 27 29 36 39 200 9 12 15 18 21 24 27 29 32 35 42 45 300 12 15 18 22 25 28 31 34 37 41 48 52 400 16 20 23 26 30 33 37 40 44 47 55 59 500 19 22 26 30 34 38 41 45 49 53 61 65 600 22 26 30 35 39 43 47 51 55 59 68 73 700 25 29 34 38 43 47 52 56 60 65 74 79 800 28 33 38 43 48 52 57 62 67 71 82 87 900 31 36 41 46 51 57 62 67 72 77 88 93 1000 35 40 45 51 56 62 67 73 78 84 95 100 1100 40 46 52 58 64 70 76 83 89 95 101 107 1200 43 49 56 62 68 75 81 88 94 100 107 113 1300 49 54 61 66 73 82 90 96 101 107 112 121 1400 55 60 67 73 80 90 99 103 109 115 120 131 - Weights above are with casing thickness of 3 mm.

- DOCUMENTS